ODI Collaborates with UVic Engineering Students to Improve Microplastics & eDNA Technology

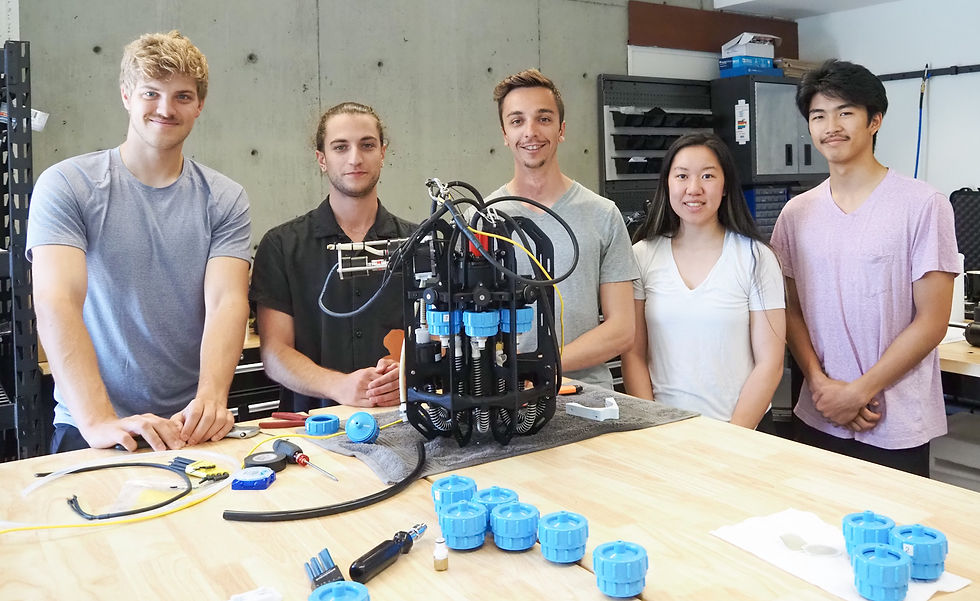

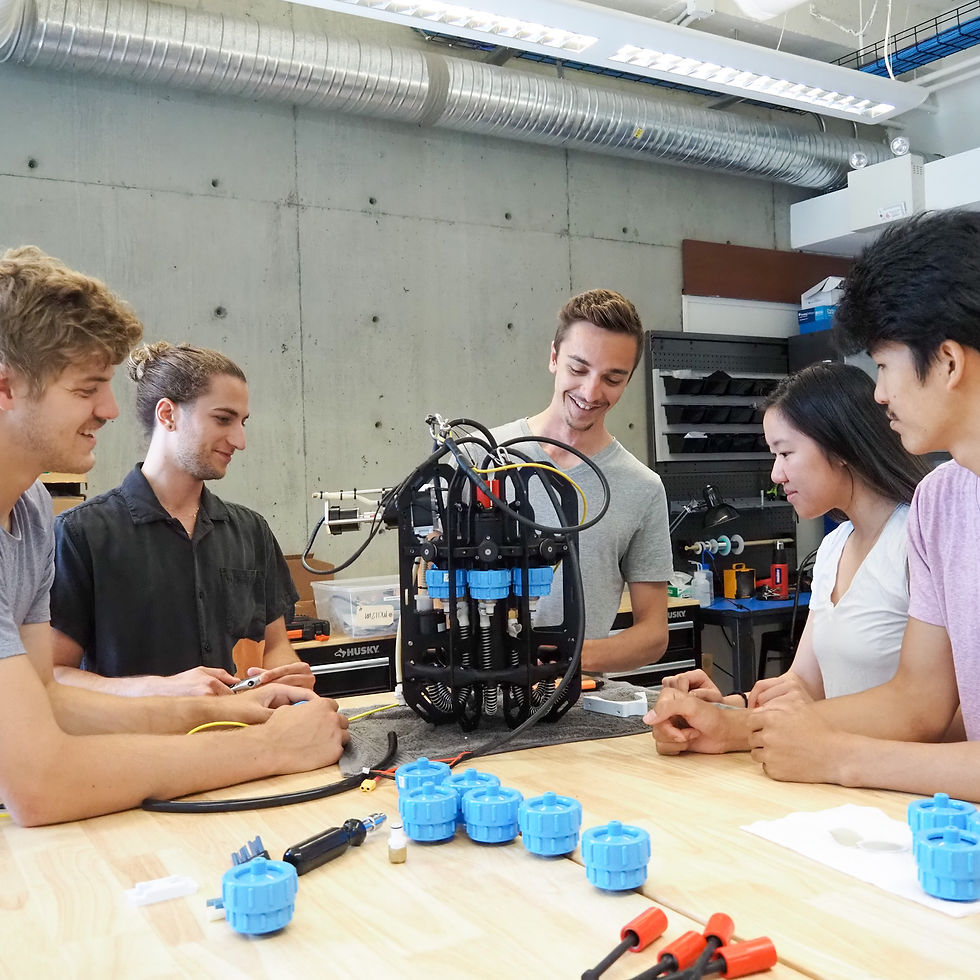

Mechanical engineering students from the University of Victoria worked with Ocean Diagnostics (ODI) to design and manufacture an innovative pump for microplastics and environmental DNA (eDNA) sampling technology. After recently presenting their working prototype at the program’s Capstone Design Showcase, the student team left ODI inspired by their ability to make a difference in an environmental space.

Filtering microplastics and eDNA from the ocean environment is extremely challenging. With ODI resources and support, mechanical engineering students Nicholas Castellani, Carmen Ho, Daniel Liew and Nic Dicesare developed and tested a novel pump design for Ocean Diagnostics’ Ascension. The new design improves the efficiency of sampling material smaller than ten microns (around seven times thinner than a strand of hair) in the ocean which helps researchers and government better monitor what is in the oceans to ultimately improve ocean health.

“Using this prototype, for example, we can see what microplastics are in the ocean which would have passed through larger filters used before. We can start to get a better picture about how much microplastics are really in the ocean..." - Nicholas Castellani

“Using this prototype, for example, we can see what microplastics are in the ocean which would have passed through larger filters used before. We can start to get a better picture about how much microplastics are really in the ocean, how small they are, how much they degrade, which microorganisms eat them and more,” explains Nicholas, the mechanical engineering student who got the team in touch with Ocean Diagnostics.

Ocean health can be monitored several ways. Researchers and government monitor pollutants, like microplastics, to help understand what human-made threats exist in ocean ecosystems and what direction they are trending (e.g. increasing or decreasing). Scientists can also monitor biodiversity using environmental DNA (eDNA). DNA that has shed from organisms is collected from environmental samples (e.g. water) and used to identify what organisms are present in certain areas.

Monitoring tools are critical to understand and improve the state of our ocean ecosystems.

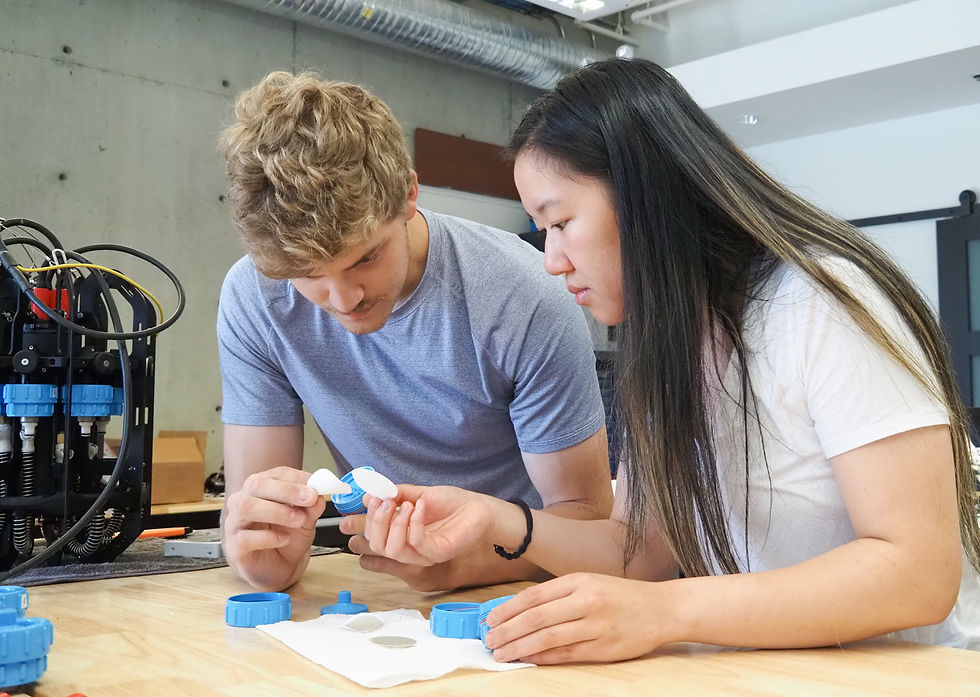

Some of the material in these samples are less than ten microns, which makes filtering microplastics or eDNA out of ocean samples an extremely challenging task.

Researchers battle between achieving fast flow rates versus using finer filters that effectively capture more material as water is filtered through. With finer filters, slower flow rates of water are typically achieved, which makes research time-consuming and inefficient.

In their final year of mechanical engineering, Nicholas, Carmen, Daniel and Nic were required to complete a capstone project to apply what they have learned throughout their university careers. They aimed to achieve higher pressure and flow rates through a much finer filter that can be used on Ocean Diagnostics’ future Ascensions.

By increasing the flow rates through a finer filter, these students aided in the design of a unique pump that can efficiently sample for microplastics, eDNA, and others, to monitor and improve ocean health.

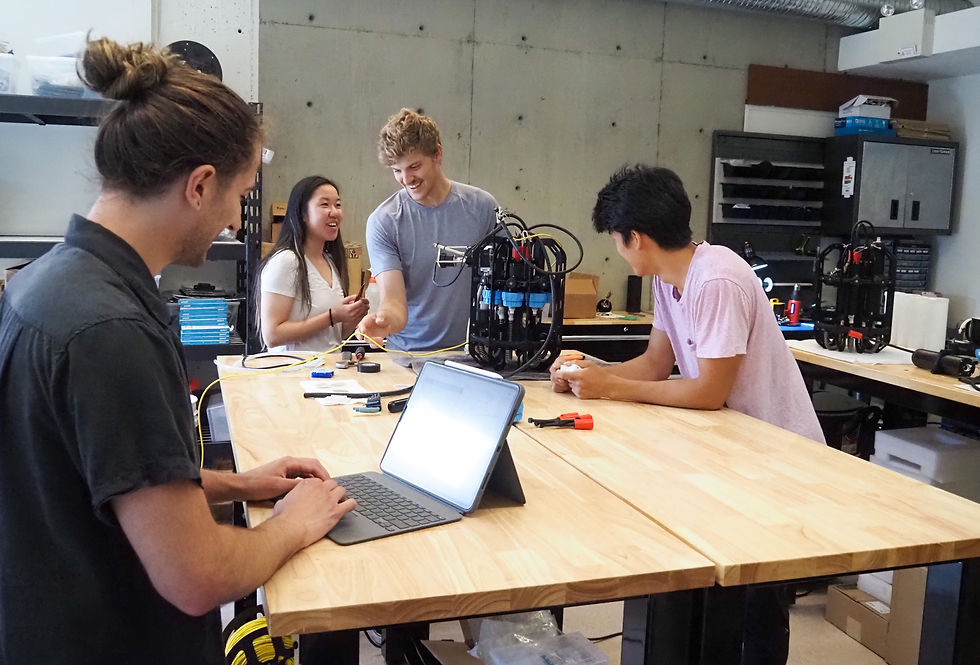

This project gave students a taste of exploratory design and manufacturing in an environmental space.

“Our work with Ocean Diagnostics was so insightful. We had to work around constraints, propose solutions, and properly experiment and design,” shares Nicholas.

"The opportunity to present what we had done, bring the physical prototype to the Capstone Showcase, was so satisfying,” - Daniel Liew

“Being able to physically manufacture the product would not have been possible to do on our own in a classroom. The opportunity to present what we had done, bring the physical prototype to the Capstone Showcase, was so satisfying,” adds team member Daniel.

Water in the environment has a lot of extra material which adds to the difficulty of sampling small items. The team applied resistance to test whether the pump would perform in the real environment, which proved a challenge.

Despite the challenge and many iterations, prototypes and “back to the drawing board” moments, Ocean Diagnostics fostered a positive learning environment.

“Rather than in school, where professors and TAs have pre-tested everything, this project involved trying to achieve specific objectives without knowing if they are actually going to work." - Carmen Ho

“Rather than in school, where professors and TAs have pre-tested everything, this project involved trying to achieve specific objectives without knowing if they are actually going to work,” explains Carmen. “We had to know when to call it quits and come up with a new idea. That was a very eye-opening experience. It was very realistic.”

Carmen shares that the experience with Ocean Diagnostics was incredibly positive.

The team often had to work backwards to figure out why certain designs did not perform, but support and feedback from the whole team at Ocean Diagnostics was encouraging. It gave the student team a sense of pride and accomplishment while working with a company aimed to improve ocean health.

“Being involved in a project like this shows that we as mechanical engineers can help in the environmental realm.” - Nicholas Castellani

Nicholas explains that before entering this space, environmental engineering felt somewhat reserved for civil and chemical engineers, but he shares excitement in establishing that there is a space for mechanical engineers in environmental management: “Being involved in a project like this shows that we as mechanical engineers can help in the environmental realm.”

It is motivating as well to know that small companies can make big environmental change.

"...I thought “wow” a small company can do a lot of work and have a big impact. That was inspiring.” - Carmen Ho

Carmen explains that before this project, she thought she would need to be in a large company to make an impact on the environment. “But seeing a company like Ocean Diagnostics,” she says, “with less than 20 employees, who send their instruments all over the world to sample for microplastics... I thought “wow” a small company can do a lot of work and have a big impact. That was inspiring.”

“It's inspiring to see the creativity that comes from a group of students working together to achieve a common goal." - Michael Giles

Michael Giles, Ocean Diagnostics mechatronic engineer, shares his enthusiasm: “It's inspiring to see the creativity that comes from a group of students working together to achieve a common goal. Their innovative solutions helped to improve the capability of our sampling instruments which have an impact on the broader community of microplastics researchers and marine scientists.”

The team at Ocean Diagnostics was thrilled to have these four students join them and bring fresh ideas to the innovative technology the team works diligently to perfect. Environmental monitoring and solutions require innovative thought and design, which can only benefit from bright minds and passion of students like Nicholas, Carmen, Daniel and Nic.

Ocean Diagnostics is an environmental impact company that diagnoses and protects our planet from the threats of microplastic pollution and biodiversity loss through innovative technology, laboratory capabilities and collaborative partnerships. We enable academia, government, industry, non-profits and the public to collect, analyze and report the scientific data needed to influence change.